We’re hearing more and more about Industry 4.0, but do we know what it is, how does it help our company, what are its advantages and drawbacks?

The concept of Industry 4.0 was first mentioned at the Hannover fair (fair dedicated to industrial technology) of 2011 with the intention of starting a project that would carry out the design and development of the intelligent factory associated with the fourth industrial revolution. A vision of computerized manufacturing with all its processes interconnected with each other making use of the Internet of Things (IoT), today called the Industrial Internet of Things (IIoT).

This revolution is marked by the emergence of new technologies such as robotics, analytics, artificial intelligence, cognitive technologies, and nanotechnology, among others. Organizations must identify the technologies that best meet their needs to invest in them. If companies do not understand the changes and opportunities that Industry 4.0 brings with them, they risk losing market share.

The term Industry 4.0 covers many concepts and purposes, but the first advances in this area involve the incorporation of greater flexibility and individualization of manufacturing processes. The automotive industry is a pioneer in the need to implement these flexible and individualized manufacturing processes, and it is where great strides are already being seen in this area because manufacturers have to adapt vehicles to individual customer needs quickly and efficiently.

What phases have we gone through until we reach the fourth industrial revolution?

The first industrial revolution arose in 1784 with the first machining system implemented in steam engines. The second revolution appeared in 1870 when the first conveyor belt was invented that facilitated mass production. Subsequently, in 1969 programmable controllers emerged, allowing electronic automation of production. Today, with the emergence of this fourth industrial revolution, all production processes are digitized through ICT (Information and Communication Technologies) and internet connection.

Industry 4.0: the technologies of the present and future

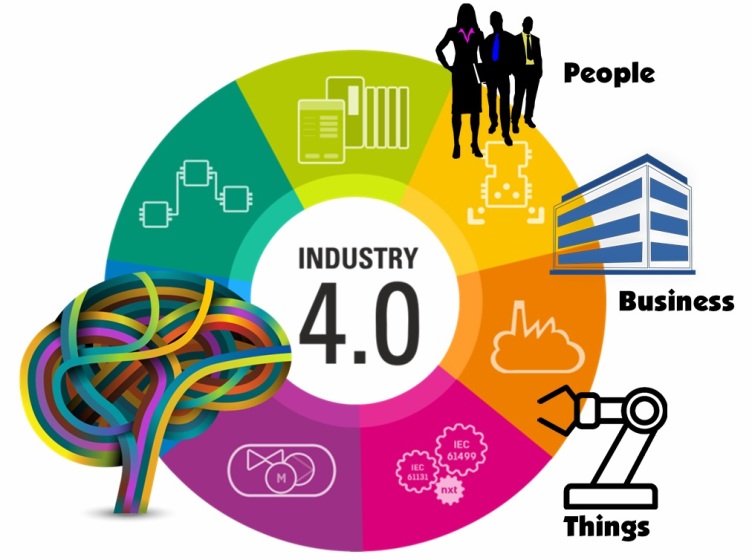

This new way of conceiving the industry has new features. The idea is that Industries 4.0 is the exponent of a new Industrial Revolution that reaches the population as a whole and increases productivity, benefiting everyone. It involves hybridization between the physical and digital worlds, shaping new interconnected multi-tenant industrial ecosystems and new business models based on the following technologies:

Industry automation intensifies

Optimizing resource usage and interconnecting robots with central software that processes information. If in the past that aspect was common, today it will be much more so, with the difference that the machinery will adapt to real-time cycles that can be modified.

Industries 4.0 can be implemented in various environments of the company

Not only in production, but also in each worker as an individual, in the company or through the organization as a whole. Therefore, it goes beyond what you would expect from a production chain.

The Internet of Things

This is one of the most well-known and widespread concepts among today’s society, since it is making its way into everyday elements and is very recognizable by all kinds of people. It refers to the way everything is interconnected within the network, all kinds of tools, appliances and other machines are also connected.

Big Data

For the acquisition and processing of huge amounts of information using mathematical models, which incorporate artificial intelligence techniques and can come to self-learn.

Cloud Computing

Where cloud services range from storage, data computing, accessibility, and application building from the hardware side to application services

Cybersecurity

Necessary for the use, processing, storage and transmission of information in industrial organizations and infrastructures, allowing the protection of assets as sensitive as innovation and information.

Robots

As autonomous machines equipped with decision-making capacity in non-predefined situations, concept called Artificial Intelligence. The “new” robots are programmed to perform various tasks, have the ability to move around them, perceive by sensors what is happening around them, communicate with other machines and/or people, and make decisions.

Augmented reality

Augmented reality is specialized technologies and software that allow to symbiotically see a real physical environment enriched with virtual elements creating a real-time mixed reality with which the user can interact to a greater or lesser degree.

Simulation

Technologies to create simulated virtual environments and predict the joint behavior of machines, processes and people in real time, seeking to experiment in controlled and virtual environments. Perform tests and obtain optimal configurations for in-plant manufacturing before even starting to produce the product.

Benefits of Industries 4.0

- Superior resource management and increased productivity.

- More efficient decision-making based on real information.

- Optimized and integrated production processes

- Direct communication between customers and organizations, which means you can better understand what customers need.

- Decreased manufacturing time in both the marketing and design of the products.

- Achieving massive and personalized production in real time becomes a more flexible process.

- Decreased percentage of defects and defects in factories, as prototypes can be tested virtually and assembly lines will be optimized.

- Logically if there is more efficiency, there will be fewer costs. Automated processes require fewer personnel, so there may be fewer errors.

- Business competitiveness is greatly increased and a better response is offered to the needs of each market.

- Greater resource efficiency results in better environmental care.

Disadvantages of Industry 4.0

- Technology is advancing, and like it, companies must, however, many of them are un prepared for these changes and risk being outdated.

- Specialized staff is required to control process automation, so that particular profile is not always found.

- It has a very high initial investment cost, although in the medium/long term it can be recovered.

- If some companies adapt the concept of Industry 4.0 and others do not, there will be a significant disadvantage for those who do not adopt this concept.

- It depends heavily on the technology, so if it fails, or there is a problem, it must be solved immediately so as not to harm the production process.

- Technology must be kept up to date due to rapid changes in technology.