3D Printers: the New Way of Creating Customizable and Economic Products

February 4, 2023

Like everything in this life, and especially with capitalism or … In evolution? Once a product stop being exclusive to certain sectors and begins to reach the rest of the world, we not only begin to discover everything that can be achieved with that good or service, but that it can improve our lives or help us to undertake (as happened with the PC). And that is why today we will talk about the 3D Printer.

Before 3D printing existed

Prototypes had to be made, carved with a lot of labor invested in wood or glued with small pieces of cardboard or plastic. They could take days or even weeks to make and often cost a fortune. Also, getting changes or modifications made was difficult and time-consuming, especially if an outside model-making company were used, and that could discourage designers from making improvements or accepting last-minute feedback.

But too changed with the advent of a better technology, called rapid prototyping (RP), which emerged in the 1980s as a solution to this problem. And that means developing models and prototypes using more automated methods, usually in hours or days instead of the weeks that traditional prototyping used to take.

What is 3D printing?

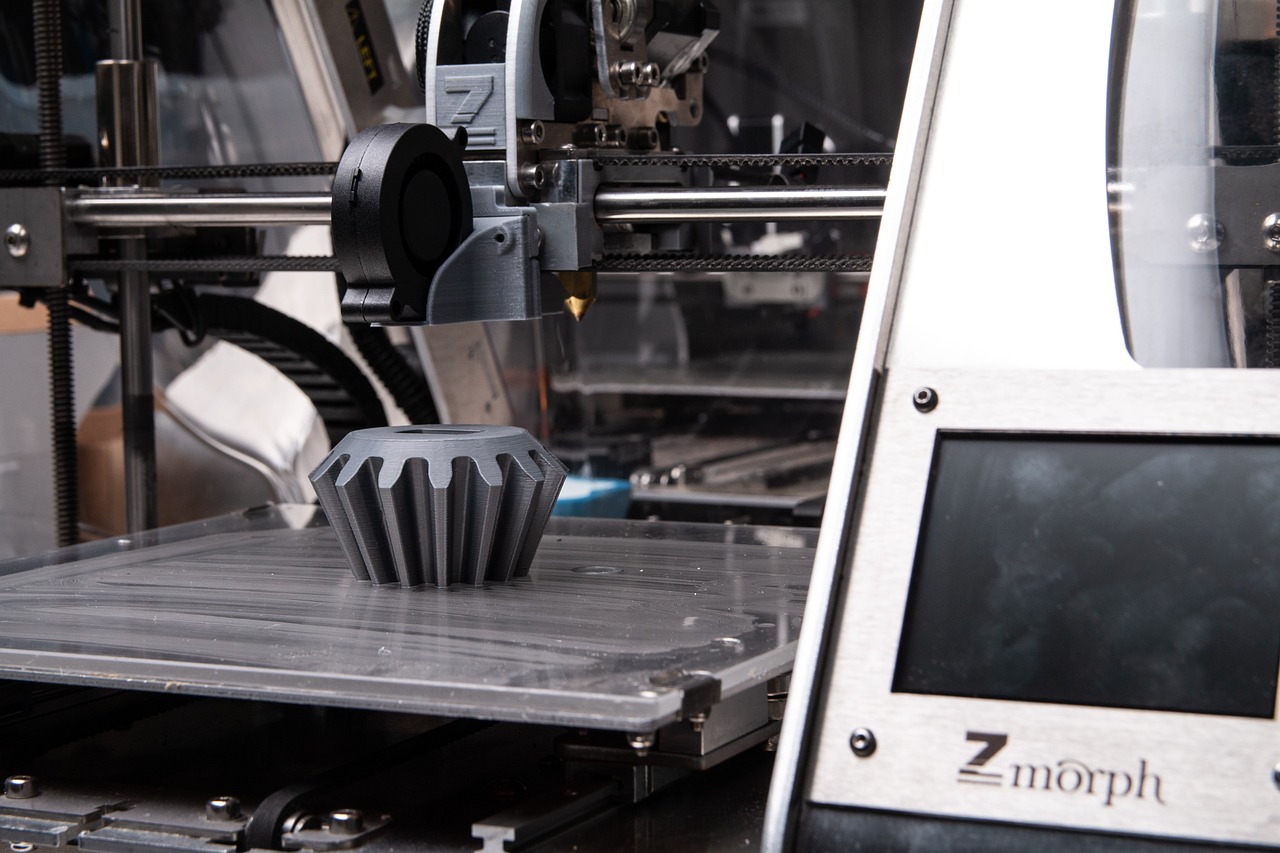

3D printing involves layering materials, such as plastics, composites, or biomaterials, to create objects with different shapes, sizes, stiffness and colors. In other words, 3D printing can provide huge savings in assembly costs because it can print already assembled products. In this way, companies can experiment with innovative ideas and numerous design variations without having to invest a lot of time, money, and tooling.

How does 3D printing work?

No special tooling is required for this technology. Instead, the part is manufactured directly on the platform-built layer by layer, which leads to a unique set of advantages and disadvantages.

The process always starts with a 3D digital model as the blueprint for the physical object. Then, the printer software slices this model into thin two-dimensional layers and converts it into a set of machine language instructions (G-code) for the printer to execute.

The materials available also vary depending on the process. Plastics are by far the most common, but metals can also be 3D printed. However, 3D printed parts are rarely ready to use right out of the machine. They usually require some post-processing to achieve the desired level of surface finish.

Once all this is clear, and if you own a 3D printer, we now move on to tell you about many useful tools that will make your daily life as easy as possible and that you can create using 3D printing devices.

Cat Feeder

The idea with this useful appliance it is to only dispense the right quantity of dry food for your Cat at the scheduled time. To accommodate the size of the food that your cat wants, there are three alternative worm gear designs.

Daily Goal Tracker

If you have TDHD or are a forgetful person, it might be challenging to maintain excellent habits, especially if you don’t monitor your development. This 3D-printed goal tracker will inspire you to complete your tasks.

Self-Watering Planter

If you are a plant lover, but they tend to die with you, because of the neglect. With this tool your conscience will remain clear, thanks to this automatic plant watered. Particularly helpful for kitchen herbs, where re-potting them in this stylish device can extend their shelf life by up to a week.